Lean Manufacturing Blog / Educational Topics

by Dan McKiernan, on Nov 18, 2019 3:06:05 PM

Accelerated and enhanced training with digital work instructions. As growing numbers of manufacturers are discovering, digital work instructions can be a game-changer. Digital work instructions are more accurate, more user …

Read Storyby Tina Kennedy, on May 6, 2018 3:18:21 PM

When making instruments or equipment that will be used on the human body there is no room for error. Consumers want to know that their pacemaker will keep their heart …

Read Storyby George Jewell, on Apr 14, 2018 12:53:25 PM

Work instructions (WI) in the past and present are typically printed on paper and many times do not represent the current processes on the plant floor. It seems that these …

Read Storyby Israel Vicars, on Apr 4, 2018 2:14:38 PM

by Israel Vicars, Software Developer at eFlex Systems In the book Outliers, author Malcolm Gladwell says that it takes roughly 10,000 hours of“deliberate practice” to become world-class in any field …

Read Storyby Israel Vicars, on Mar 30, 2018 9:09:24 AM

by Israel Vicars, Software Developer at eFlex Systems What does the “e” in eFlex stand for? Electronic? Excellent? Effervescent? Emulsifier? The acronyms in our everyday conversation become background noise after …

Read Storyby Dan McKiernan, on Sep 23, 2015 4:43:00 AM

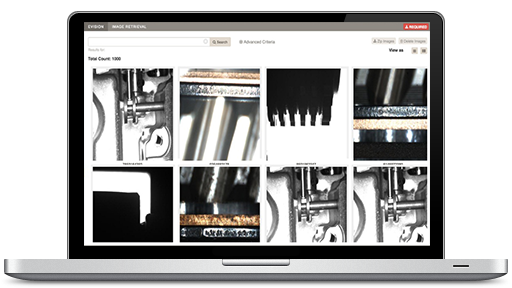

Manufacturers are beginning to realize the need to retain images as product is processed through their systems to help with warranty claim management, improve quality and perform root cause analysis …

Read Storyby Dan McKiernan, on Sep 8, 2015 5:15:00 AM

To explain how eFlex Assembly might support the assembly line issues you are facing, the following are 9 common scenarios we frequently hear from engineers. 1. Over (or Under) Producing …

Read Storyby George Jewell, on Sep 8, 2015 4:40:07 AM

There has been an ongoing debate over “zone” vs “distributed” control architecture for assembly line systems. It is the old-school “zone” approach verse the “distributed” approach, which takes advantage of …

Read Storyby Dan McKiernan, on Dec 18, 2013 1:30:00 PM

GM realizes “weeks to hours” reduction in line change and transmission build dynamics at Toledo Powertrain, resulting from Flexible Assembly Configuration System (FACS) and Siemens control/communication. A tried and true …

Read StoryThe Blog

Our team is a creative bunch that loves learning and pushing the limits to find the best solutions for today's lean manufacturers. Internal discussions at the office might range from new features that manufacturing process control software should have to machine learning, blockchain technology, or what the future of AR on the plant floor looks like. Check out our blog for opinions, news and trends that we find interesting and think you might too!

- Articles & Publications (7)

- Connected Process Control (33)

- Development Process (4)

- Digital Work Instructions (17)

- Educational Topics (9)

- Events (3)

- Food Industry (1)

- Industry 4.0 (32)

- Insider (9)

- Kitting (3)

- Lean Manufacturing (42)

- Manufacturing Culture (6)

- Manufacturing Execution System (1)

- Manufacturing Integrated Platform (7)

- Medical (2)

- News (28)

- Operator Training (2)

- Opinion (37)

- Partnerships (3)

- Press (4)

- Product Details (2)

- Quality Management (20)

- Team Building (2)

- Technology (23)

- Traceability (6)

- Training (1)

- Vehicle Assembly (3)

- February 2018 (6)

- May 2018 (6)

- September 2015 (5)

- November 2016 (4)

- May 2022 (4)

- January 2017 (3)

- March 2017 (3)

- June 2018 (3)

- February 2019 (3)

- November 2019 (3)

- February 2022 (3)

- June 2023 (3)

- July 2023 (3)

- November 2023 (3)

- February 2012 (2)

- December 2016 (2)

- March 2018 (2)

- April 2018 (2)

- March 2019 (2)

- July 2019 (2)

- September 2019 (2)

- January 2020 (2)

- January 2022 (2)

- March 2022 (2)

- May 2023 (2)

- August 2023 (2)

- October 2023 (2)

- December 2023 (2)

- January 2024 (2)

- March 2024 (2)

- April 2024 (2)

- November 2024 (2)

- December 2024 (2)

- August 2012 (1)

- November 2012 (1)

- March 2013 (1)

- June 2013 (1)

- September 2013 (1)

- November 2013 (1)

- December 2013 (1)

- February 2014 (1)

- July 2014 (1)

- September 2014 (1)

- February 2015 (1)

- March 2015 (1)

- August 2016 (1)

- October 2016 (1)

- February 2017 (1)

- October 2017 (1)

- July 2018 (1)

- August 2018 (1)

- October 2018 (1)

- January 2019 (1)

- April 2019 (1)

- May 2019 (1)

- June 2019 (1)

- October 2019 (1)

- March 2020 (1)

- June 2020 (1)

- October 2020 (1)

- October 2022 (1)

- April 2023 (1)

- February 2024 (1)

- May 2024 (1)

- June 2024 (1)

- August 2024 (1)

- September 2024 (1)