Improve Reliability & Reduce Costs.

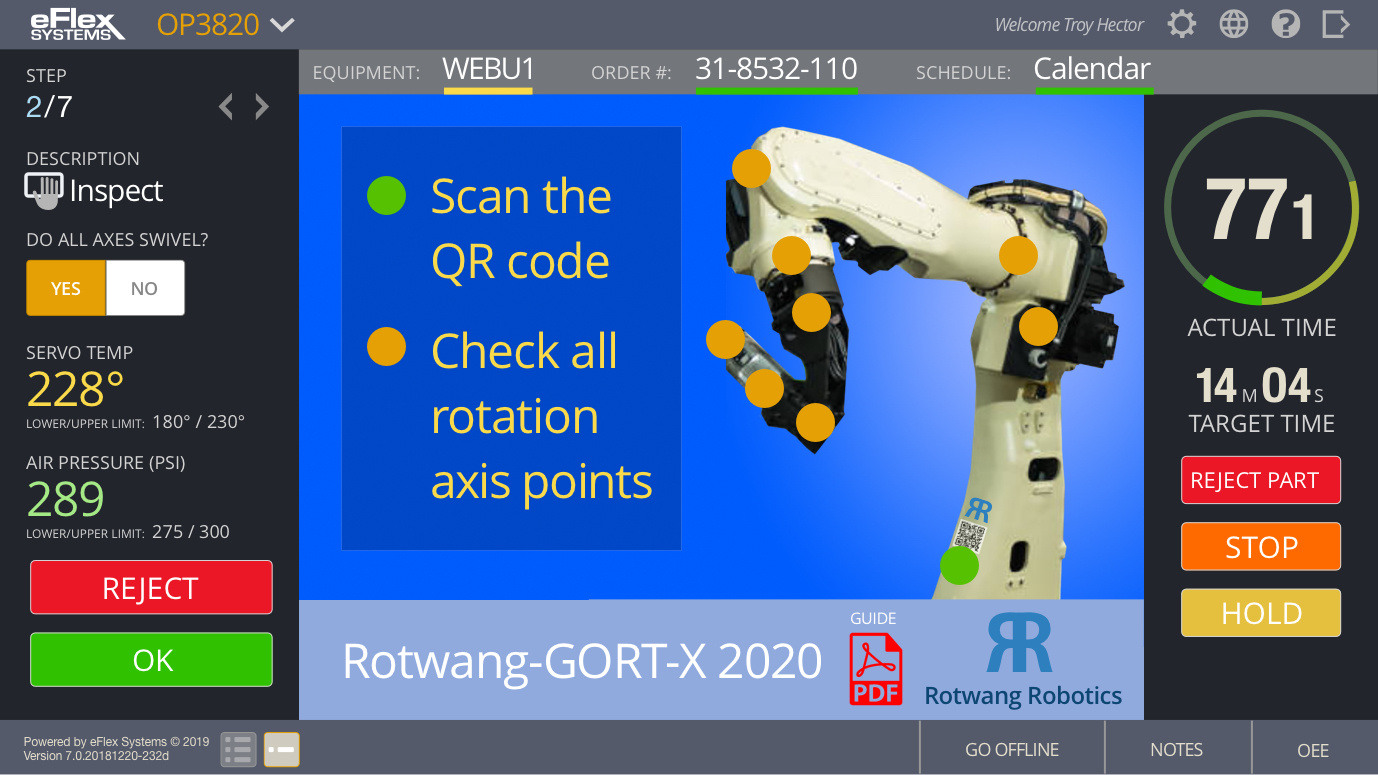

Reactive maintenance can be extremely costly from production errors, downtime, labor costs to reduced asset life expectancy. With Epicor Connected Process Control, manufacturers can easily develop digital standardized maintenance procedures, enforce best practices, collect granular process data, with a permanent digital record for asset management and regulatory compliance.