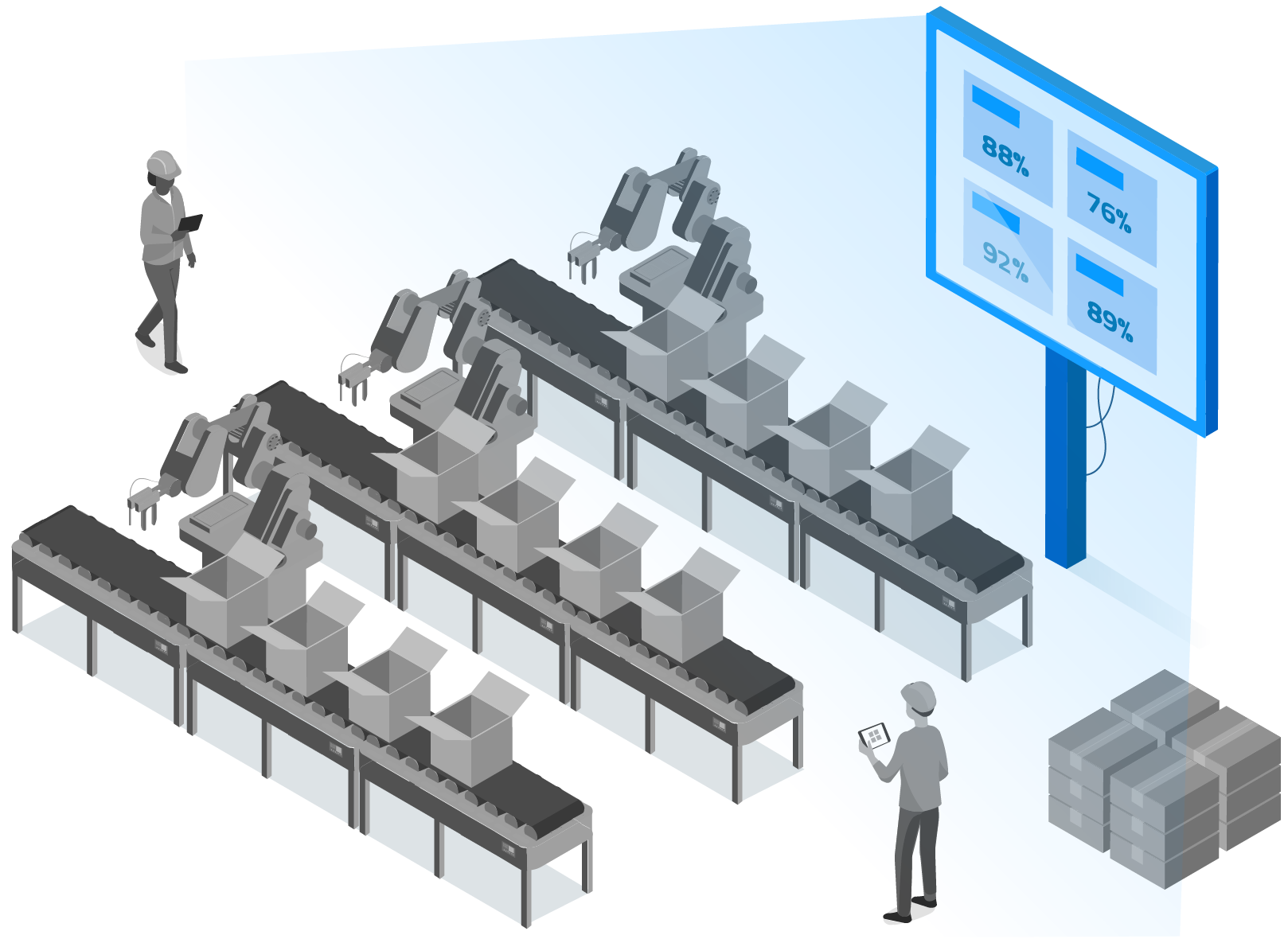

Machine State & Overall Equipment Effectiveness

Increase productivity, improve quality and cut costs to successfully compete in today's market. With Epicor Connected Process Control's OEE, capture data directly from machines/equipment and organize it in a manner that drives peak performance. Visualize content on any web-capable device such as a large overhead display, any PC connected to the network or a tablet.