Intelligent Data Flows.

Simplified Digital Transformation

While the cost of traditional layers on the plant floor can be extremely expensive and labor intense – from hardware and integration costs to programming and data analysis needs, Epicor Connected Process Control provides significant cost savings and reduces the need for separate layers on the the plant floor – PLCs, HMIs, SCADA and MES/MOM systems.

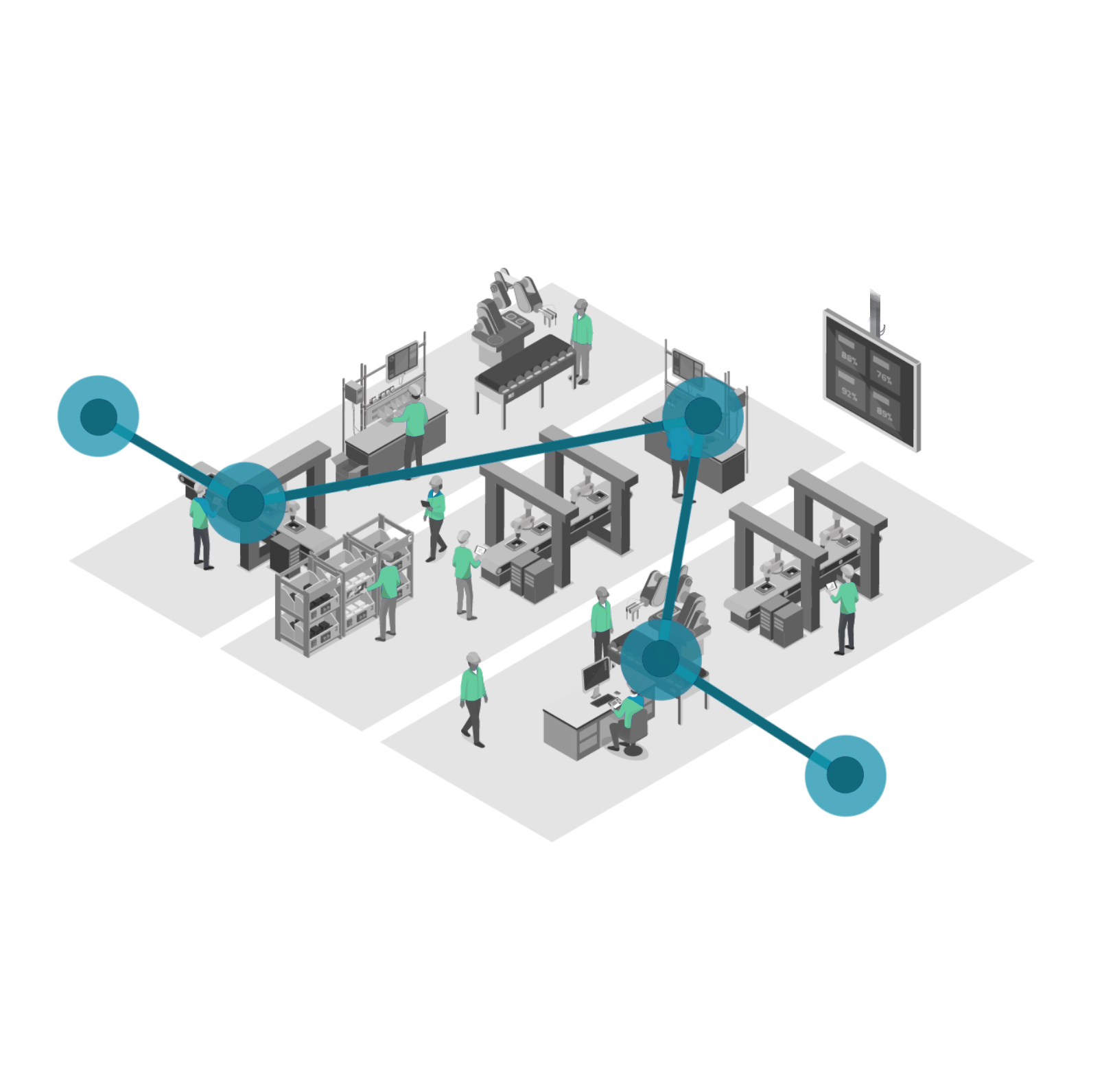

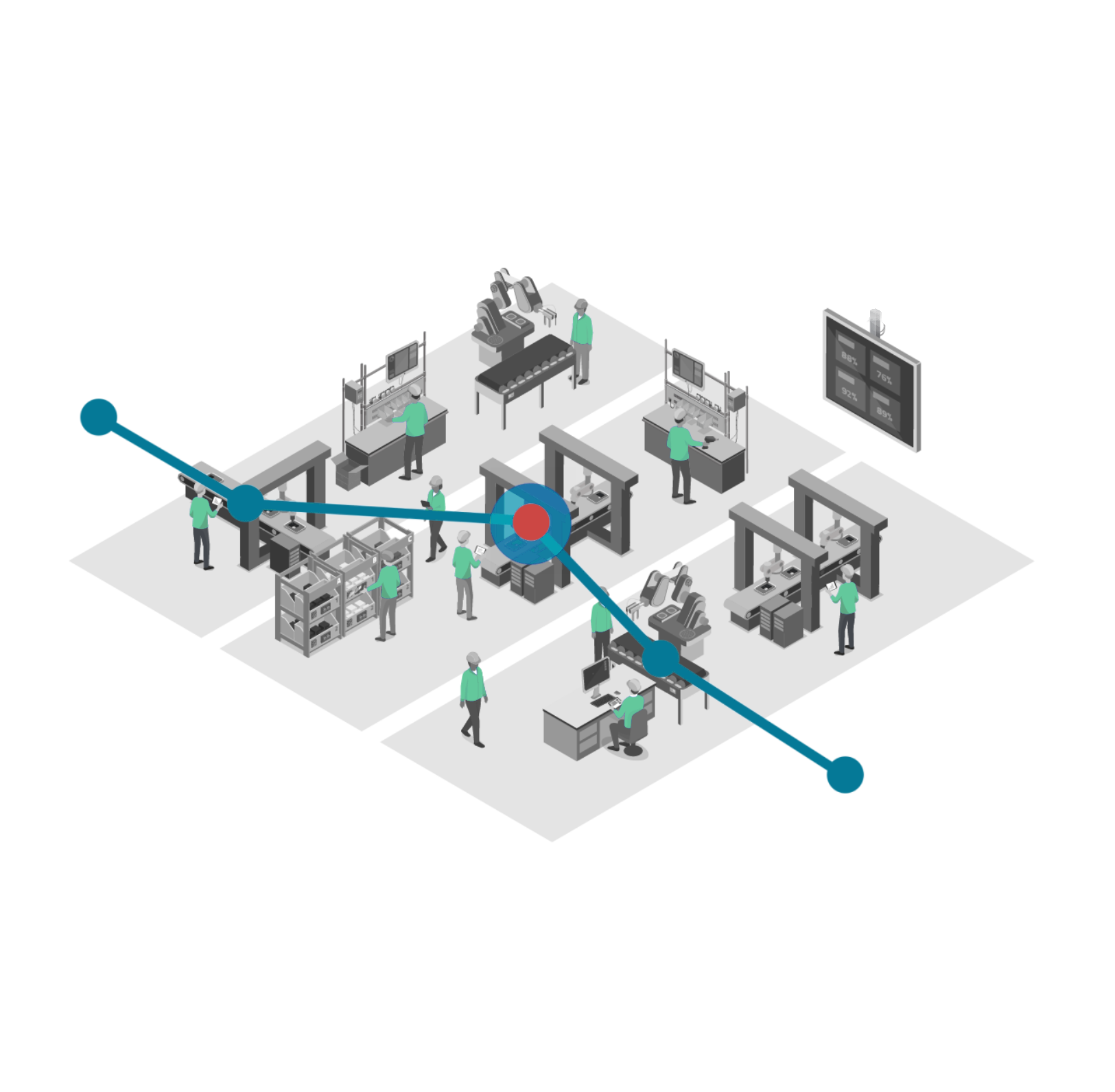

One application environment with one common navigation and flow from the control of I/O at the sensor level to advanced analytics reporting. Connectivity and direct control covering a wide range of PLCs, sensors, applications and virtually any data source. Intelligent data collection and flow from the shop floor to the top floor for business intelligence and a competitive advantage.