Utilizing Digital Work Instructions for Manufacturing COVID-19 Mitigation Strategies

by Tina Kennedy, on Jun 5, 2020 3:47:19 PM

As manufacturers begin to ramp up operations with newly implemented COVID-19 mitigation strategies, it’s clear Industry 4.0 technologies are more relevant than ever. The pandemic has proved that companies that had previously invested in digital technologies were better prepared for survival, able to adapt to new requirements and implement strategies more quickly. In a post COVID-19 era, Industry 4.0 technologies will become even more critical in helping manufacturers become more flexible, agile, data driven, and able to withstand disruptions.

As manufacturing operations reopen, a challenge companies may face is workforce availability and training. Will there be enough staff available? How to protect them from potential COVID-19 exposure? And, will they be trained and competent to perform necessary tasks, especially if they have been gone away from their processes for an extended period of time. It is likely that job descriptions and qualifications will have to be reviewed to validate assigned operational roles and responsibilities and make sure competencies are met. Also, it may be necessary to have staff complete re-training, cross-training or undergo a re-qualification process to make sure they are able to perform job duties correctly but also to receive new safety information and policies pertaining to COVID-19.

With the use of simulated training centers or technology labs utilizing digital work instructions built on IoT technology, visual guidance with validation at each step allows for quicker training times and retention for employees. Simulated training also alleviates the need for congested classroom style training which could increase health risk exposures. With web-based browser capabilities, management can monitor remotely when employees have finished training, completed tasks appropriately and are ready to get back on the production floor.

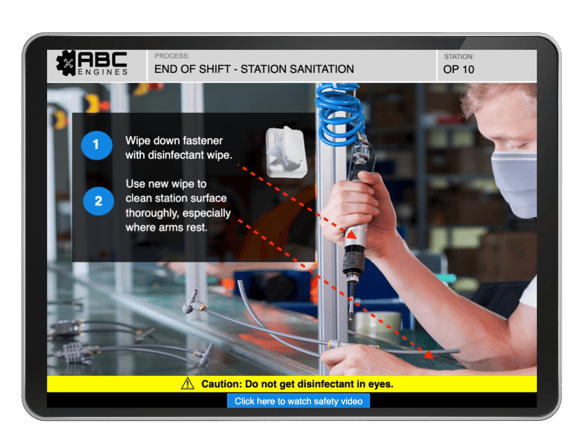

New COVID-19 safety precautions and requirements also increases the need for organizations to update their current work instructions and operating procedures. This will apply to not only manufacturing operations but support functions at all levels. Utilizing paper-based work instructions can be extremely time consuming and also increase COVID-19 exposure risk as operators share and handle binders and new paper instructions at the station level. Digital work instructions provide a quicker, safer pathway to update new procedures and safety requirements. Team members working remotely can receive notifications as changes are made, collaborate and provide feedback, and give their digital approval with the click of a button when work instructions are ready to go. In real-time, digital instructions can be sent to the appropriate stations with no need to update binders or increase employee exposure touching papers at the station level. Also, with digital work instructions, new safety videos, URL links, PDFs, and more can be embedded so operators have quick access at the station level for all necessary information related to PPE, MSDS or OSHA safety requirements.

In order to navigate COVID-19 and any potential future disruptions, manufacturers need to make digital adaptations and embrace Industry 4.0 technologies. They need to modernize, move forward, and innovate, permitting them to become agile, data driven and best in class.