Setting Operators Up for Success with Digital Work Instructions

by Jason Bullard, on Feb 22, 2022 8:11:34 AM

For decades—even generations—innovators in manufacturing have worked hard to find ways to minimize the chaos and complexity of manufacturing and production environments.

While new technologies have unlocked impressive new advances in consistency and quality, it’s the human element in the manufacturing space that has the greatest potential for tech-driven innovation and refinement.

By using technology strategically and thoughtfully, decision-makers in the manufacturing space can set their operators up for success, allowing them to work smarter and accomplish a wider range of complex tasks with greater speed and facility. In basic terms, that means giving them the tools, training, and tech they need to not just get the job done, but to achieve potentially dramatic improvement in efficiency and performance.

What follows are a set of principles and best practices that can help any manufacturer set their operators up for success:

Simplicity

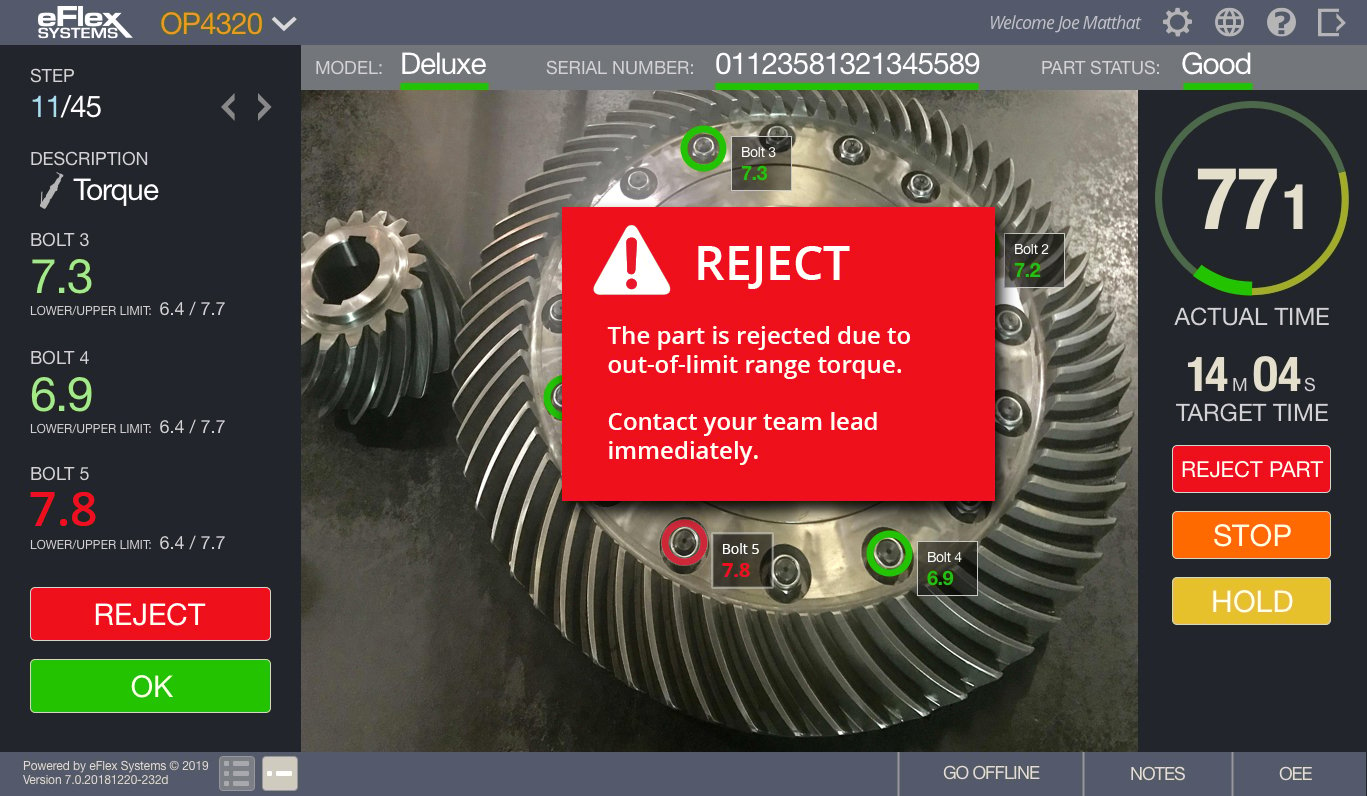

Digital work instructions have helped to transform modern manufacturing environments. They alleviate the costly and time-consuming demands of printing and replacing hard copies of work instructions and are dramatically easier to change or update to accommodate variation or customization. The best digital work instructions are streamlined and simplified, designed to present operators with everything they need to know at a glance—and with no excess information. Ironically, the complexity of new manufacturing tech is ideally suited to deliver the straightforward simplicity that helps set operators up for success.

Flexibility

One of the most exciting advances in the manufacturing technology space is the ability to use new adaptive tech platforms that provide operator-specific training and instruction. With instruction/oversight tailored to the individual worker, operators are given the level of detail and guidance suited to their training and expertise. Newer operators or workers adjusting to a new task or process can be given more detailed step-by-step guidance, with confirmation that parts and processes have been completed according to specified standards. As they become more experienced and adept at mastering tasks and processes, instructions can become correspondingly simpler and shorter to optimize efficiency and productivity.

Clarity

Too much information can be as much of a problem as too little. Few things are more counterproductive to efficiency than confusing, ambiguous, or overly detailed instruction. Only show the operators the details they need to perform their tasks. Clarity and concision are the goals of modern manufacturing guidance and instruction.

Knowledge sharing

One of the most powerful ways to set operators up for success is to ensure that acquired knowledge is not lost when experienced operators retire or change circumstances. The potential loss of that historical knowledge is a huge concern, particularly at a time when demographic realities have accelerated a generational shift in the manufacturing workforce. Technology can unlock creative and impactful new vectors for knowledge sharing, delivering the kind of mentor-driven guidance and insight that might otherwise be lost. That can be achieved not just through text and imagery, but through videos, GIFs, audio files, and other nontraditional media.

Efficiency

The best digital platforms can help build and disseminate work instructions quicker and more readily and accommodate customization and variation. Because they can deliver that guidance without having to retrain operators, manufacturers can save significant time and money—all while realizing a more consistent and higher-quality result.

Training

Setting operators up for success begins at the beginning. Modern digital platforms can dramatically boost training and onboarding processes. The potential improvements in training quality and efficiency alone are eye-opening, transforming what might have previously taken weeks of supervised instruction for a new operator to learn into days of solo training to achieve the same result.

By leveraging modern technology platforms, manufactures are now able to be more flexible, efficient and provide better tools to operators, setting them up for success. Making a more meaningful and measurable impact on performance and outcomes in everything from quality control to speed and consistency.