Digital Work Instructions Made Easy

by Josh Easterling, on Feb 1, 2022 9:15:00 AM

I want to digitize work instructions, but do I have to start from scratch?

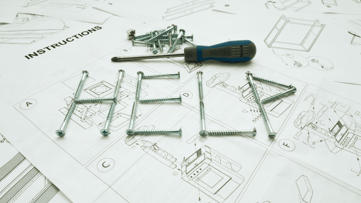

As manufacturing evolves and becomes more digital, many companies are looking to transfer from paper-based work instructions to a digital format for their operators. However, some companies are uncertain about taking the leap as they have already spent a lot of time and resources creating paper-based instructions and feel they would need to essentially start over. The thought of that much rework is daunting and has companies skeptical to begin their digital journey.

As manufacturing evolves and becomes more digital, many companies are looking to transfer from paper-based work instructions to a digital format for their operators. However, some companies are uncertain about taking the leap as they have already spent a lot of time and resources creating paper-based instructions and feel they would need to essentially start over. The thought of that much rework is daunting and has companies skeptical to begin their digital journey.

Luckily, there are software platforms now available that allow you to import current work instructions that you have already developed into a digital format. For example, eFlex System's platform has a built-in Work Instruction Editor (WIE) which can assist you in managing and storing your work instructions and files. You can recreate work instructions from scratch or you can import files such as JPEGs, TIFFs and PNGs. Once imported, you can then edit over those file types as needed.

Within WIE, you can also import file types such as PDFs, GIFs, MP4s and even STLs. With imported PDF files, you have the ability to configure what page the operator sees for each assembly step/task which saves significant amounts of time for the operator. Also, on a quick note, GIF use is becoming very popular for visual work instructions. Operators themselves admit that when it comes to word lengthy work instructions, they don't want to take the time to read all of the information, so they just guess what they should be doing. Obviously that has a high potential for quality issues and errors. GIFs play on a repetitive loop, so the operator just needs to look up for a quick moment to view exactly what he/she needs to reference to complete their task.

Having the ability to utilize existing paper-based instructions can make your digital transformation easier and quicker. It provides a great starting point, and when imported into a digital format can provide your employees with materials that look familiar to them. Additionally, work instructions can be more slowly and systematically moved to the digital environment, where animations, hyperlinks, templates, and approval workflows can be used. When making any kind of change in manufacturing, it is important to make small changes and gradually introduce new items so you do not overwhelm operators. Not everyone embraces changes in the same way, so it is important to be thoughtful during these types of transformations.

If you are interested in learning more about how eFlex Systems can assist you with your digital transformation, please feel free to email us at sales@eflexsystems.com or request a free online demo on our website at www.eflexsystems.com.