Digital Work Instructions are Changing the Future of Manufacturing

by Tina Kennedy, on May 13, 2022 3:49:17 PM

Some people might say that the tried and true method of training new operators is to have them shadow a veteran employee. But what if there's no one with the experience to train the new operator? That's where digital work instructions come in. They can take the place of a human instructor, making it possible to train new operators anywhere in the world. And they're not just for training new employees – they can also be used for experienced operators as assembly processes are updated or new products are introduced.

As digital technology continues to evolve, more and more companies are looking for ways to integrate it into their operations. One area where digitalization is having a major impact is in the realm of work instructions. By moving from paper-based to digital work instructions, factories can become more efficient and responsive to changes. Additionally, digital work instructions can provide operators with greater guidance and support, leading to improved product quality. In an era of Industry 4.0, digital work instructions are becoming increasingly essential for businesses that want to stay competitive. Thanks to the benefits they offer, digital work instructions are helping to shape the future of manufacturing.

As digital work instructions become more common, it's important to understand how they can improve product quality. In a paperless factory, digital work instructions are displayed on screens that can be easily seen by operators. This allows for more accurate operator guidance, which reduces the risk of human error. Additionally, digital work instructions can be updated in real-time as processes change. This ensures that operators are always working with the most up-to-date information, which leads to increased product quality. Also, advanced digital work instructions can enforce process control, enable IoT devices such as torque controllers at point of use and ensure parameters are within specs. As industry 4.0 technologies continue to develop, digital work instructions will become an essential part of the manufacturing process and provide advanced training and significant error proofing benefits.

JEM Work Instructions

Job Element Monitor (JEM) is a web-based digital work instruction application that enables you to manage your company’s assembly process and work procedures. This digital solution allows you to go paperless, optimize training times, error proof assembly, while maximizing quality and compliance standards. At eFlex, we've seen customers decrease new operator training times from approximately 2 weeks to 2 days after implementing JEM.

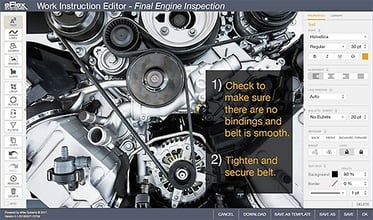

With JEM's built-in work instruction editor, users can quickly and easily create digital work instructions. Import photos, GIFs, or link to videos and PDF documents. Easily markup photos with additional text, icons and images, to highlight key information and provide maximum clarity. No need to utilize outside resources like Word, Excel or Powerpoint for work instruction creation. The functionality is embedded in the application.

Work instructions and tasks are displayed in real-time. Get 100% time capture for each process task start & stop. Cycle time indicator shows targeted time for each station as well as actual time per station. Station data gives management the tools they need to make data-driven operational decisions.

To learn more about JEM click this link for a short video overview.

For questions please contact an eFlex sales engineer at 833-463-3539 or request a quick online demo. We're here to help you go digital.