Our trusted clients

MIP is powered by the MIP Data— providing detailed, integrated granular manufacturing process data down to the most basic task level. All in one place.

Intelligent MIP Data enables powerful end-to-end people and data collaboration across the enterprise. Everyone from the shop floor to the top floor can see the status of your production line and get real-time actionable insight. A lean competitive advantage to maximize quality and throughput while reducing costs.

MIP is simple to configure without any programming. One integrated platform. It's all connected. No more complex layers.

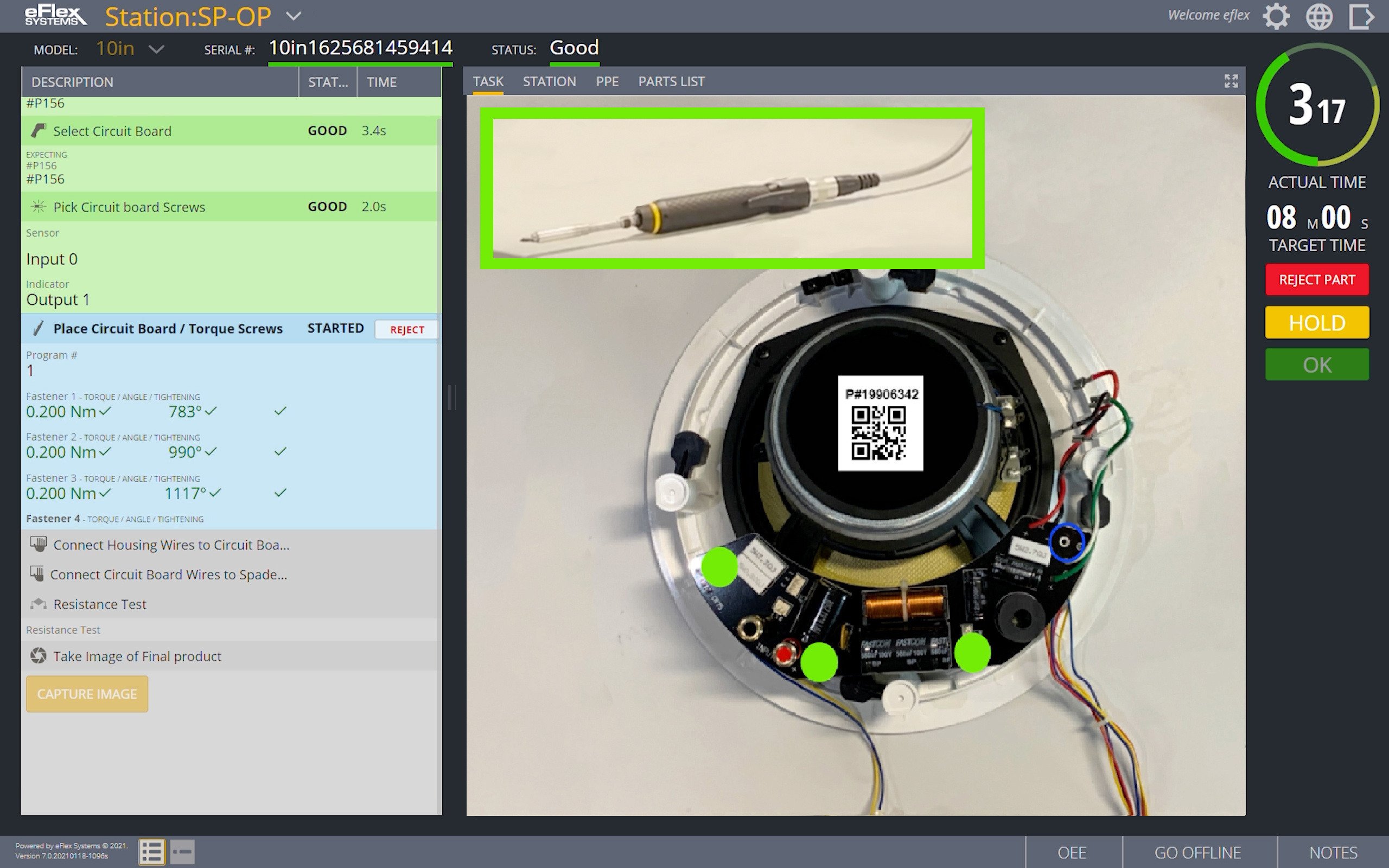

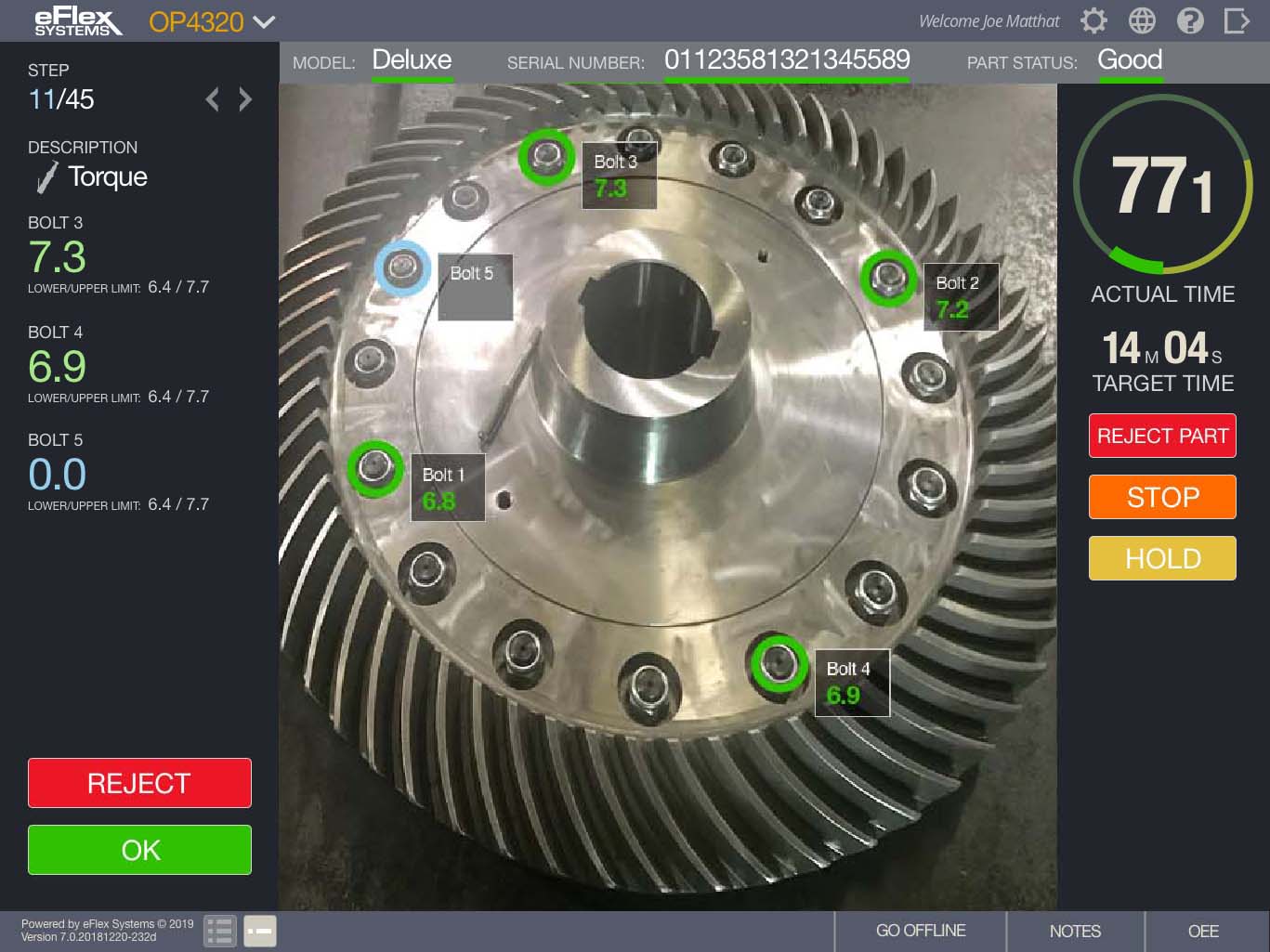

Easy, plug-n-play, IoT device connect. Automatically display, verify and collect device level data at the station level.

Complexity under control! Advanced process control for low and high mix assembly. Easily error proof operations.

Collect process data and cycle times down to the task level. Quickly identity problem areas and improvement initiatives.

Whether your environment is high or low mix assembly, our solutions will fit your process control needs. MIP data gives you a flexible and free-flowing manufacturing landscape.

Easily manage variability and high mix process control with MIP. Our system intuitively reacts to the individual components and options of your BOM without the need to configure every possible variant of your product.

MIP provides an environment to easily connect plug-n-play IoT devices and PLCs for device level control and data collection, all without any necessary programming. Sequential process control and error proofing becomes seamless, guiding operators every step of the way.

MIP Data gives you a high-level overview of the plant floor. Seamlessly rebalance lines with drag-n-drop, adjust process controls, and attune any sudden discrepancies.

Tenpoint Crossbow is a world class manufacturer of products that are recognized as an industry standard for safety, accuracy, precision engineering, durability, performance, and power. To ensure their quality standards, they partered with eFlex, integrating digital product traceability into their assembly process.

It’s all connected so it doesn’t need months to configure or get started. Simply turn on the solutions you need now and add more as you grow. Fast-track paperless manufacturing, empower shop floor teams, enforce process and quality control and get the business intelligence you deserve.

Are you growing frustrated with using Word, Excel, Powerpoint or homegrown systems to create and manage work instructions, SOPs and training documents? Tired of paper and inefficient processes? Go paperless on the plant floor with Job Element Monitor (JEM), an easy-to-use work instruction module within MIP. Easily configure digital instructions, fast-track training and enforce process & quality control.

Visual guidance and validation at every step allowing for quicker training times and employee retention.

Collect unlimited amounts of process data with built-in and customizable data collection fields.

No need to utilize outside resources like Word, Excel or Powerpoint for work instruction creation. The functionality is embedded in the app!

Provide automatic feedback loops to operators and never leave them guessing what to do next.

Get a digital record of part marriage for serial number, batch or lot. Meet compliance standards and protect against warranty claims.

Digital process control provides a digital twin of your assembly operations. Easily visualize steps and rebalance in minutes not days.

With eFlex Vision, easily record & search 2D images to further control quality spills, warranty claims and improve root cause analysis.

Minimize scrap and reduce costs with rework/repair strategies. Collect traceability process data for all reworked and rejected parts.

Manufacturing traceability is becoming a critical requirement for industries globally to reduce risks, meet regulatory requirements and stay competitive. Whether you are looking for a basic or advanced traceability solution, eFlex has you covered. Easily enable, enforce and track the quality process. Get a digital birth certificate for every product built down to the component and task level.

Access to data is the first step in harnessing the power of data. With eFlex's Manufacturing Integrated Platform, users get access to process data down to the task level. Our Business Intelligence app turns MIP data silos into powerful reports and dashboards for granular, real-time visibility and insight of operations. Now that's a competitive advantage!

Quickly and easily identify and manage quality spills, recalls, warranty claims and compliance issues. Always monitoring. Always improving.

User configurable data displays. Ensuring that every employee, from the shop floor to the front office, is on the same page.

Granular, real-time visibility and insight of operations for continuous improvement initiatives and a competitive advantage.

Monitor it. Measure it. Improve it. Ability to enter notes and reason codes for faulted, starved or blocked stations.

Run MIP locally or in the cloud. You decide what works best for your operation. Both are web-based with direct access to data anywhere, anytime.

Scalable, modular solutions for station, plant or enterprise wide needs. Choose the solutions you need now to get started and scale when ready.

Quick and easy configurations, allowing changes to be made in minutes not days. No programming needed. Web-based with ability to make changes off-site if needed.

We want your digitization goals to be a success. Our dedicated support team along with the online eFlex Learning Center will help you every step of the way.

Watch a video about our digital work instructions – Job Element Monitor (JEM), to learn how our platform solutions easily integrate and control manufacturing processes.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec dictum viverra arcu porta commodo. Ut viverra diam velit, lobortis eleifend ligula pulvinar ut. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec dictum viverra arcu porta commodo. Lorem ipsum dolor.

Location

eFlex Systems - an Epicor Solution

210 W. Tienken Rd.

Rochester Hills, MI 48306

Contact Sales

Quick Links