Lean Manufacturing Blog / Product Details

by George Jewell, on May 3, 2018 12:59:11 PM

News Release - Rochester Hills, MI - May 3, 2018 eFlex systems is pleased to announce that Open Protocol V1 and V2 has been added to our JEM Assembly product …

Read Storyby Dan McKiernan, on Sep 8, 2015 1:00:00 PM

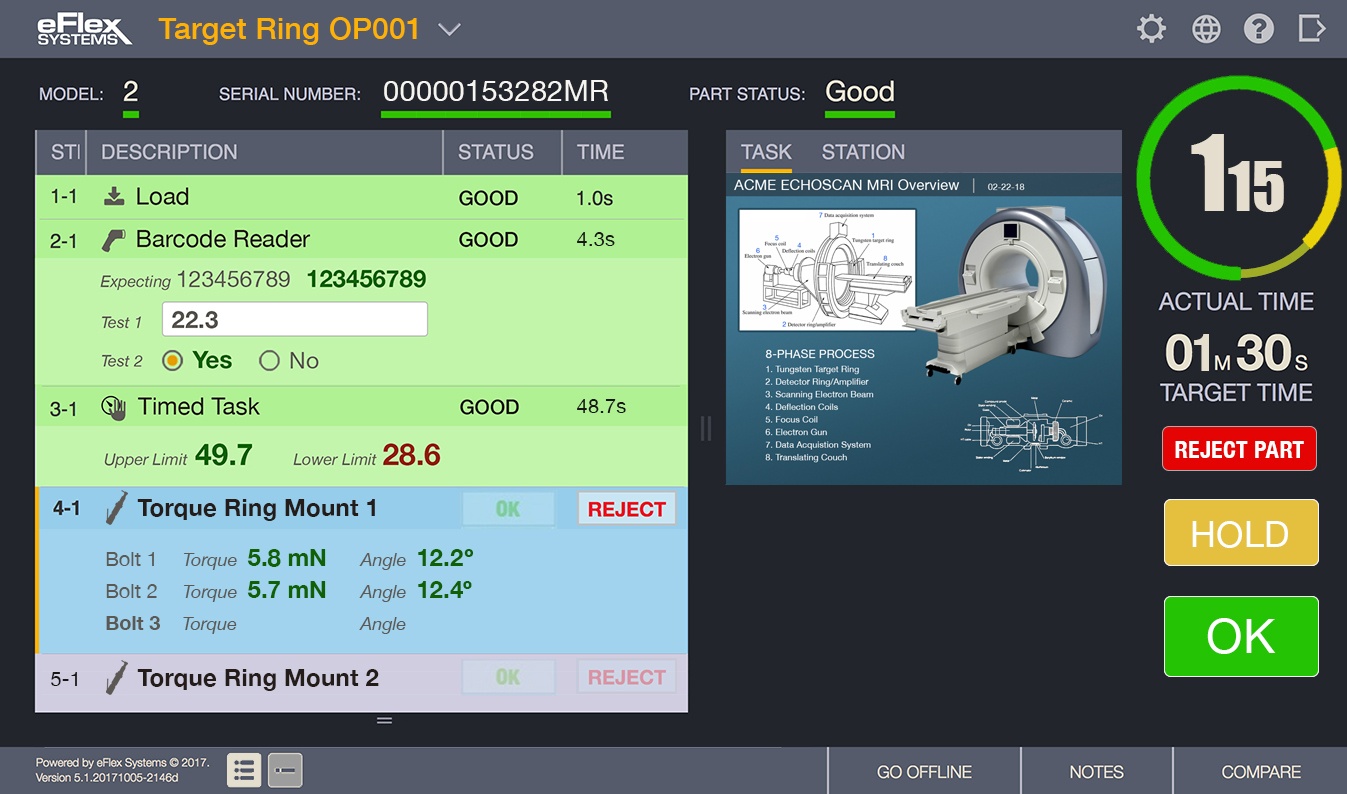

The eFlex Assembly infrastructure contains a Process Configuration Tool, Process Improvement Tool and Process Engineering Tool that are accessible and visible from the office to the plant floor. Process Configuration …

Read StoryThe Blog

Our team is a creative bunch that loves learning and pushing the limits to find the best solutions for today's lean manufacturers. Internal discussions at the office might range from new features that manufacturing process control software should have to machine learning, blockchain technology, or what the future of AR on the plant floor looks like. Check out our blog for opinions, news and trends that we find interesting and think you might too!

- Articles & Publications (7)

- Connected Process Control (24)

- Development Process (4)

- Digital Work Instructions (17)

- Educational Topics (9)

- Events (3)

- Food Industry (1)

- Industry 4.0 (30)

- Insider (9)

- Kitting (3)

- Lean Manufacturing (35)

- Manufacturing Culture (5)

- Manufacturing Integrated Platform (7)

- Medical (2)

- News (28)

- Operator Training (2)

- Opinion (28)

- Partnerships (3)

- Press (4)

- Product Details (2)

- Quality Management (20)

- Team Building (2)

- Technology (20)

- Traceability (6)

- Training (1)

- Vehicle Assembly (3)

- February 2018 (6)

- May 2018 (6)

- September 2015 (5)

- November 2016 (4)

- May 2022 (4)

- January 2017 (3)

- March 2017 (3)

- June 2018 (3)

- February 2019 (3)

- November 2019 (3)

- February 2022 (3)

- June 2023 (3)

- July 2023 (3)

- November 2023 (3)

- February 2012 (2)

- December 2016 (2)

- March 2018 (2)

- April 2018 (2)

- March 2019 (2)

- July 2019 (2)

- September 2019 (2)

- January 2020 (2)

- January 2022 (2)

- March 2022 (2)

- May 2023 (2)

- August 2023 (2)

- October 2023 (2)

- December 2023 (2)

- January 2024 (2)

- March 2024 (2)

- August 2012 (1)

- November 2012 (1)

- March 2013 (1)

- June 2013 (1)

- September 2013 (1)

- November 2013 (1)

- December 2013 (1)

- February 2014 (1)

- July 2014 (1)

- September 2014 (1)

- February 2015 (1)

- March 2015 (1)

- August 2016 (1)

- October 2016 (1)

- February 2017 (1)

- October 2017 (1)

- July 2018 (1)

- August 2018 (1)

- October 2018 (1)

- January 2019 (1)

- April 2019 (1)

- May 2019 (1)

- June 2019 (1)

- October 2019 (1)

- March 2020 (1)

- June 2020 (1)

- October 2020 (1)

- October 2022 (1)

- April 2023 (1)

- February 2024 (1)

- April 2024 (1)